OUR BUSINESS

EPC Division

KIYEON E&C. thinks about the environment of Korea.

KIYEON E&C. thinks about the environment of Korea.

| type of factory | source | Types of VOC substances |

|---|---|---|

| Stamp and ink manufacturing plant | Automotive, electronic product painting, dryer, metal, glass, etc. | Benzene, Toluene, Xylene, Naphta, Alcohols, Esters, organic solvent, etc. |

| Solvent, adhesive and synthetic resin manufacturing plant | Plastic, plywood manufacturing process | Stvlene, Aldehydes, Esters etc |

| chemical plant | Petrochemical, organic synthesis process | Benzene, Toluene, Xylene, Aldehyde, Alcohols, organic acids, etc. |

| Odor Substance Handling Plant | Fertilizer, feed, fire extinguisher manufacturing process, etc. | Amines and sulfur compounds |

| automotive and petrochemical | Various processes such as BTX process | Aliphatic/aromatic hydrocarbons, benzene, etc. |

| textile manufacturing plant | Chemical fiber weaving process, etc. | Acetone, Alcohols, CH₃S₂ etc. |

| dry cleaning | large laundry | Chlorinated hydrocarbons, gasoline, etc. |

| metal and electronics | PCB factory, etc. | Chlorinated hydrocarbons, ester alcohols, organic acids, etc. |

| Etc | Tobacco dryer, perfume manufacturing process, etc. | Alcohols, Esters |

| technology | principle | apply | characteristic |

|---|---|---|---|

| catalytic combustion | Combustion through catalyst contact at 200~400℃ |

mostly combustible gas | High efficiency, catalyst replacement required, low operating cost, catalyst poisoning |

| direct combustion | Combustion with direct heat source at 800~900℃ |

mostly combustible gas | Advantageous to high concentration, increase in operating cost, deterioration in device durability, and Nox generation problems |

| Bio Reactor | biodegradation | most odorous substances | Freeze prevention facility required |

| condensation | cooling and condensation | high boiling point substances | Advantageous for removing high-concentration substances |

| absorption | Activated carbon, Zeolite adsorption | most odorous substances | Regeneration and pretreatment units required |

| chemical cleaning | Neutralize with acid and alkali | ammonia, amines | Acid/alkaline wastewater treatment facility required |

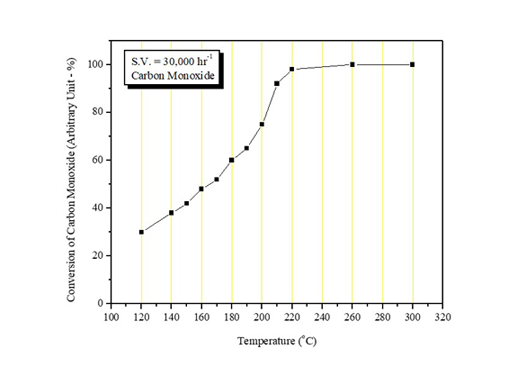

Conversion of Carbon MoCOide over the ZEROCO-III Catalyst(a high-temperature catalyst)